commercial PASSIVaTION

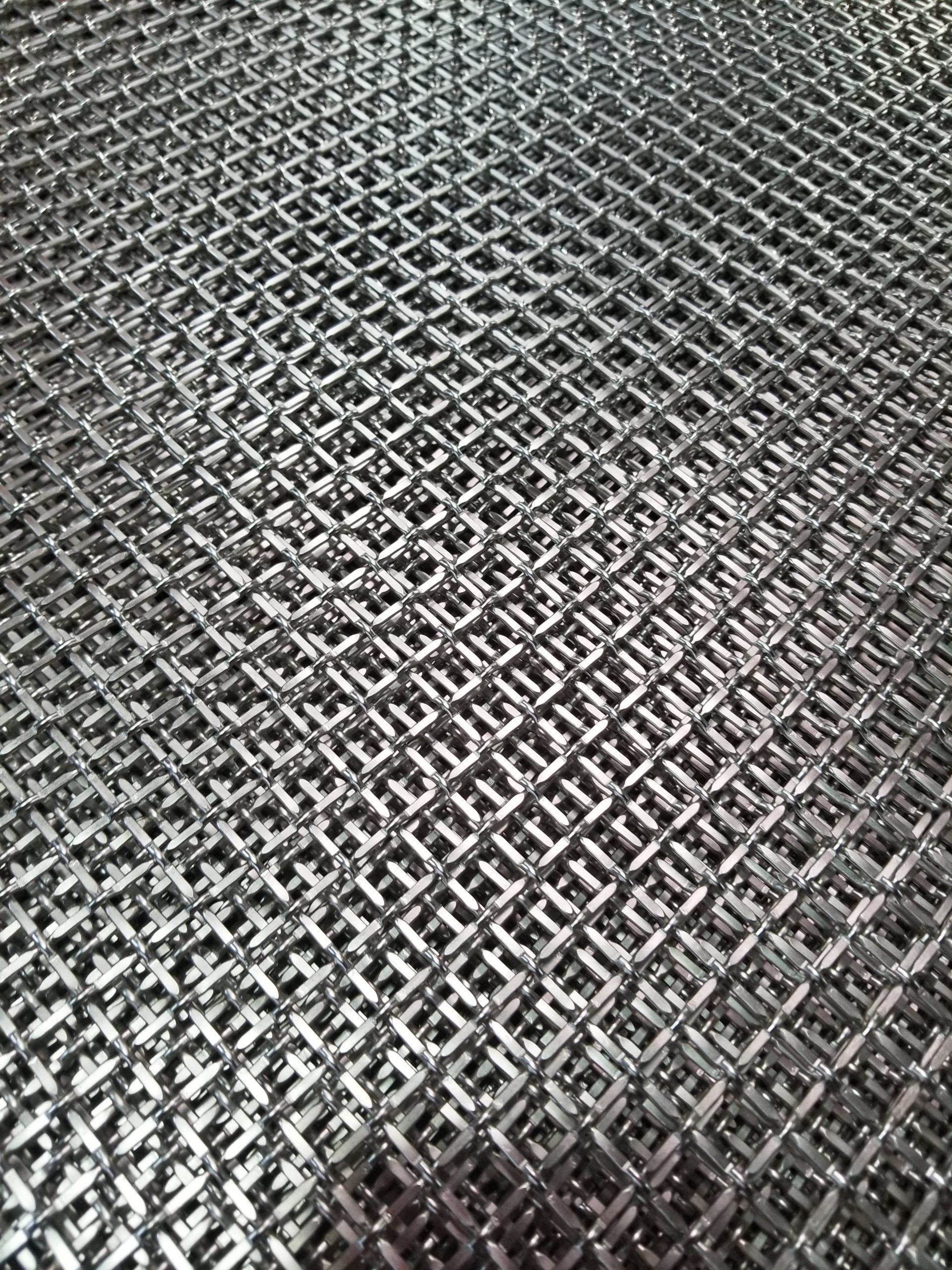

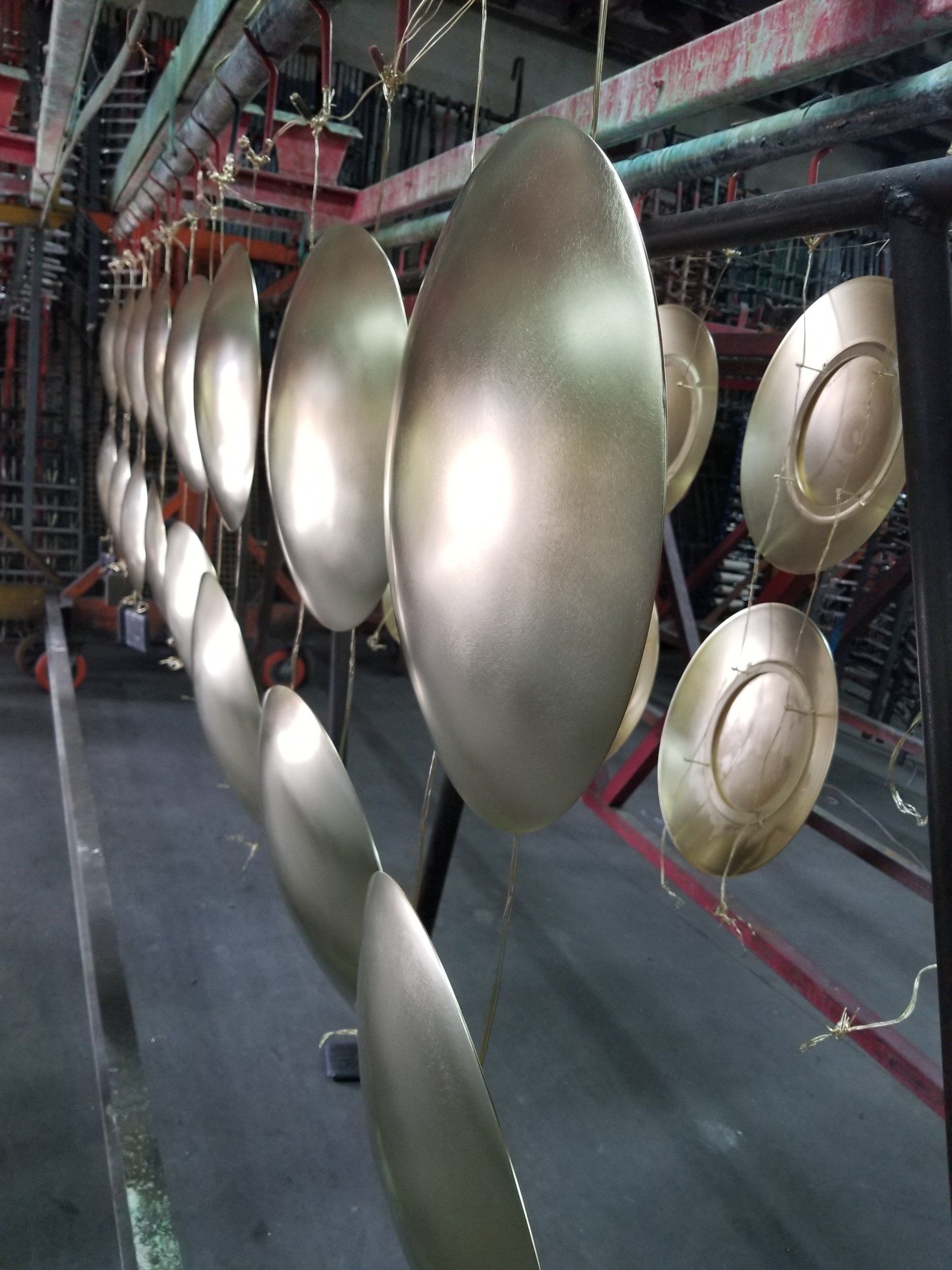

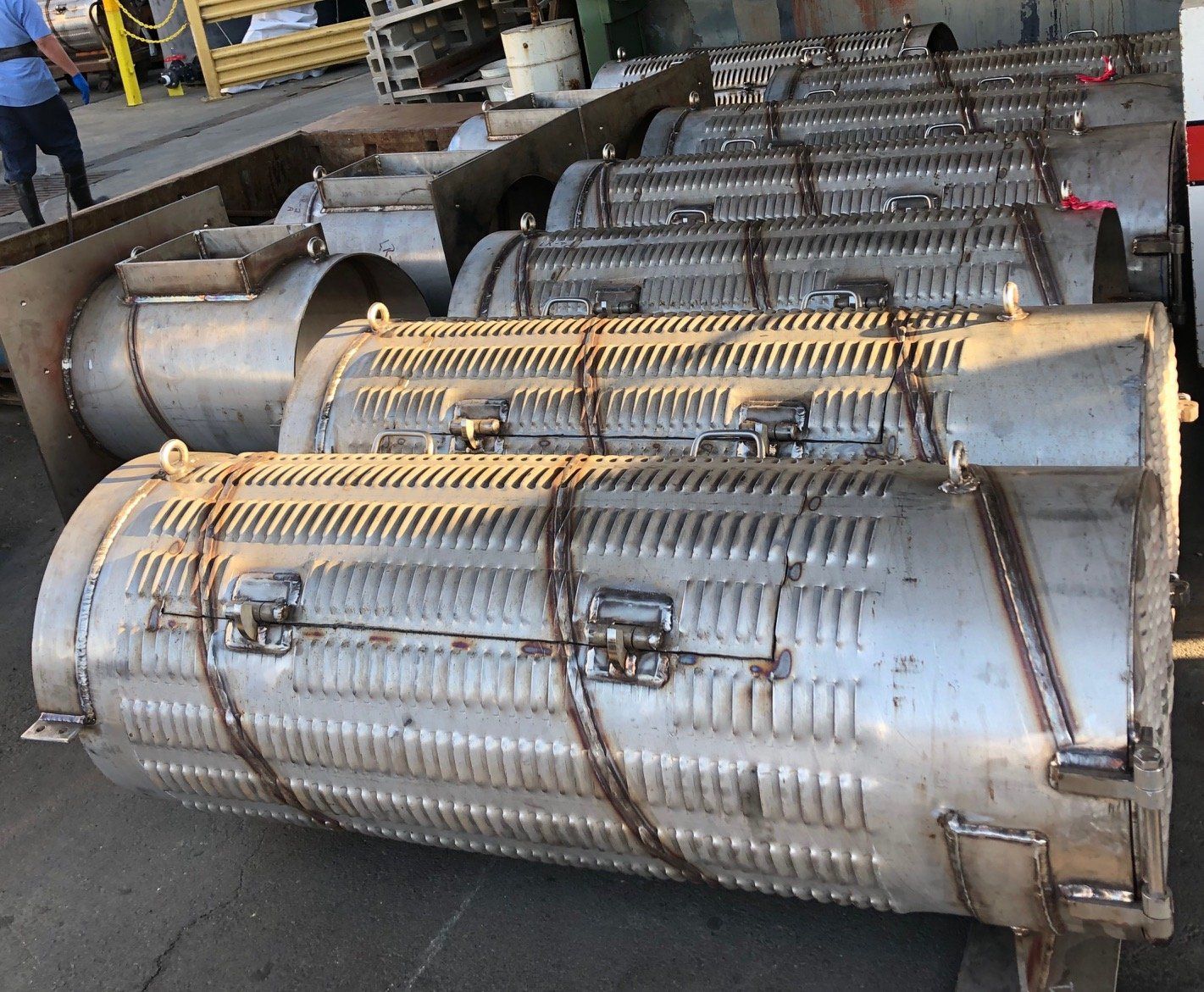

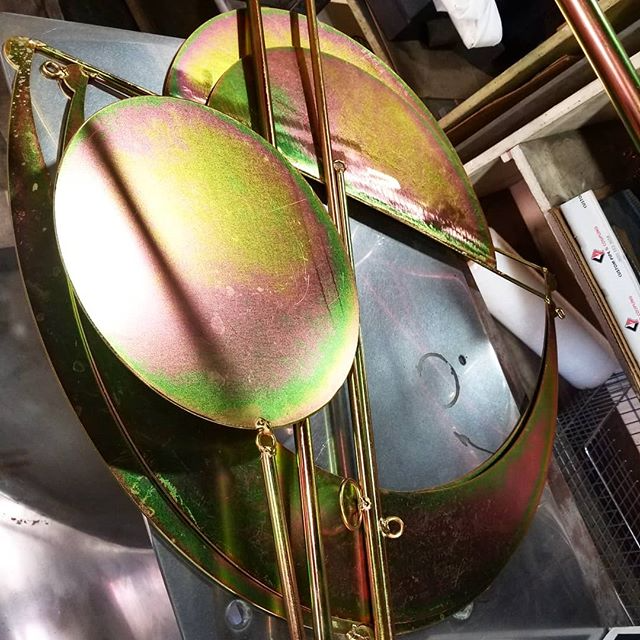

Passivation Process

Passivation, in physical chemistry and engineering, refers to a material becoming "passive," that is, less affected or corroded by the environment of future use. Passivation involves creation of an outer layer of shield material that is applied as a microcoating, created by chemical reaction with the base material, or allowed to build from spontaneous oxidation in the air. As a technique, passivation is the use of a light coat of a protective material, such as metal oxide, to create a shell against corrosion. Passivation can occur only in certain conditions, and is used in microelectronics to enhance silicon. The technique of passivation strengthens and preserves the appearance of metallics. In electrochemical treatment of water, passivation reduces the effectiveness of the treatment by increasing the circuit resistance, and active measures are typically used to overcome this effect, the most common being polarity reversal, which results in limited rejection of the fouling layer. Other proprietary systems to avoid electrode passivation, several discussed below, are the subject of ongoing research and development.

323-268-6353

323-268-6353

323-268-6353

323-268-6353