Pickling Stainless Steel

COMMERCIAL PICKLING

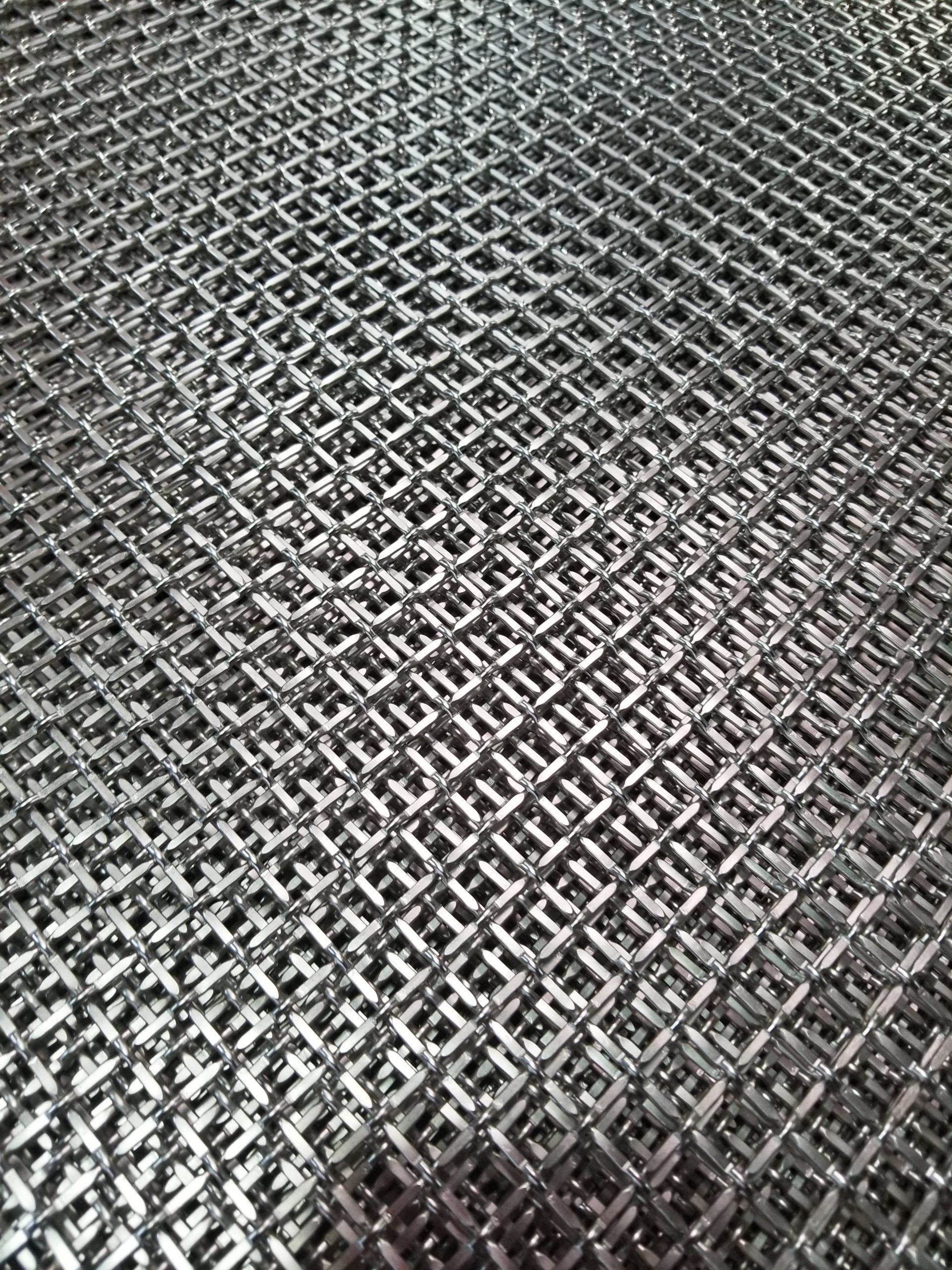

Pickling or chemical descaling, is a metal surface treatment used to remove impurities, such as stains, inorganic contaminants, rust or scale from ferrous metals, copper, and aluminum alloys. A solution called pickle liquor, which contains strong acids, is used to remove the surface impurities.

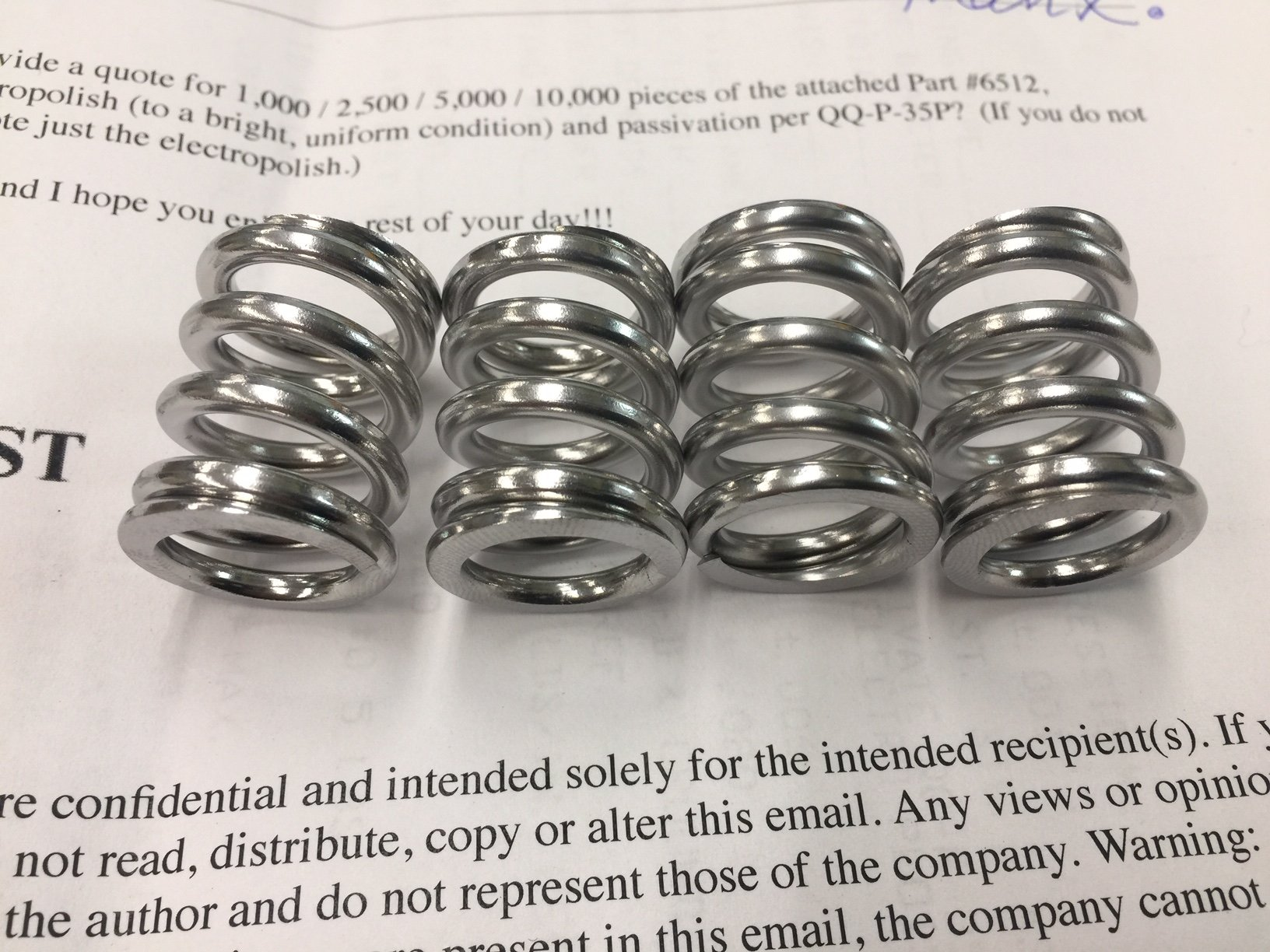

Pickling is but one of several pretreatment steps available for preparing an article for further processing such as passivation or electropolishing, or to perform a superior cleaning operation of welded structures.

Prior to pickling, the heavy surface soils such as oil, grease, buffing compounds, drawing compounds, some scale, heavy rust, dye and paint markings, tape, adhesive residue and other foreign substances must be removed. This step may be accomplished by the use of alkaline cleaners, solvent cleaning, vapor degreasing, ultrasonic cleaning, steam cleaning, water-jetting, or other mechanical cleaning.

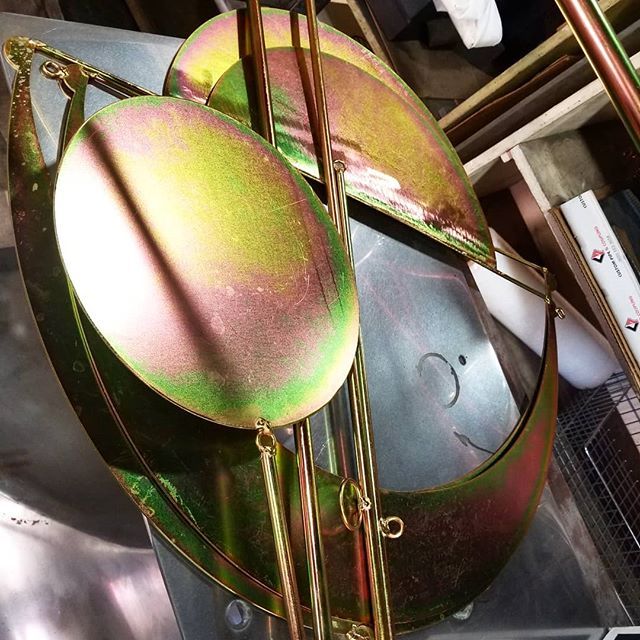

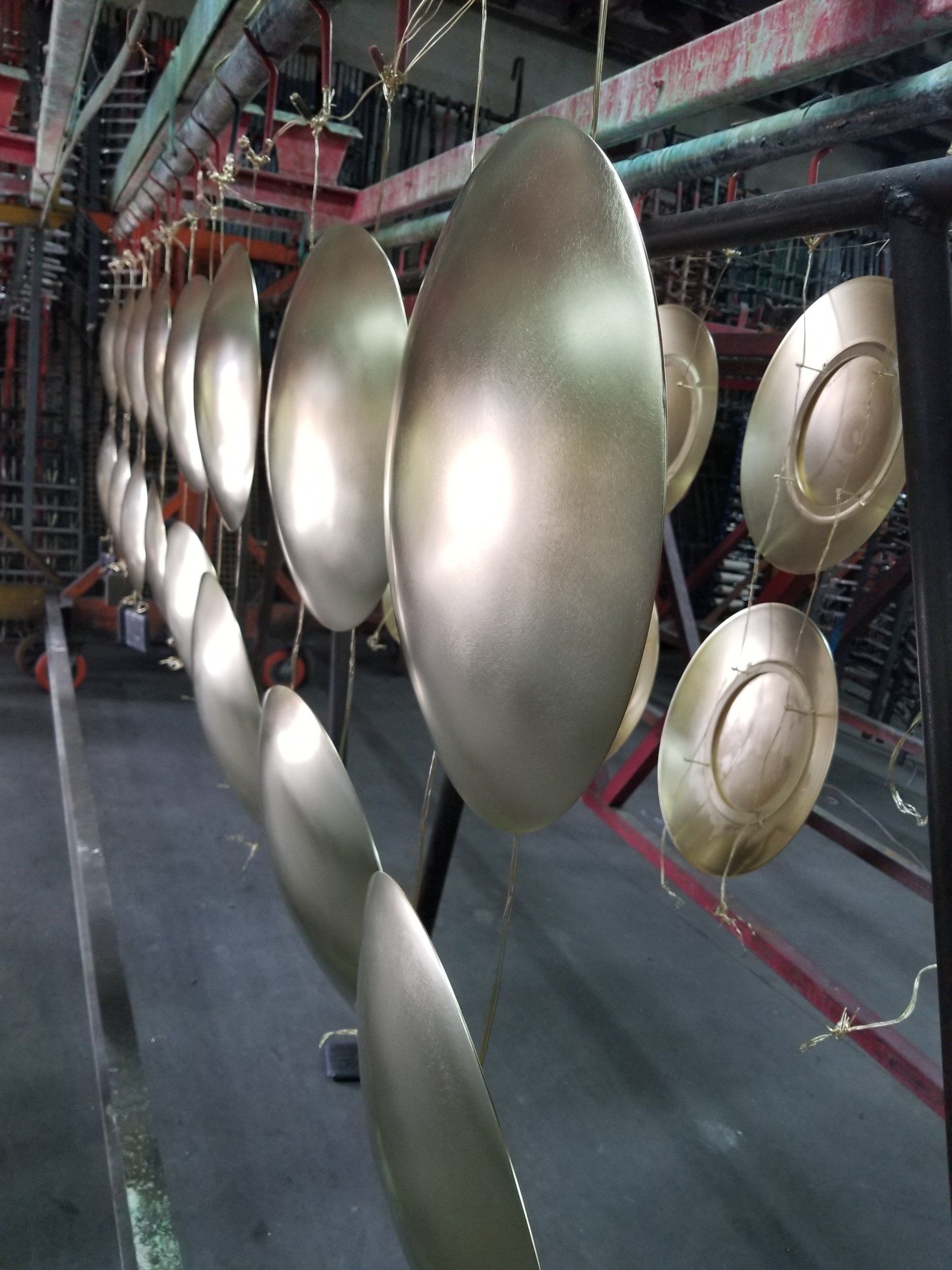

Pickling is typically performed to remove tightly adherent oxide films resulting from hot-forming, heat treating, welding and other high temperature operations. Welding or heat treatment often produce complex oxides that can vary in color. All these oxides are generally referred to as "scale" and must be removed

At General Brite Plating, we provide electroplating, electroless plating, electropolishing, and pickling services as needed to meet the needs of our clients. We can pickle or passivate any part that can be transported to our facility.

323-268-6353

323-268-6353

323-268-6353

323-268-6353